Closed Impeller System

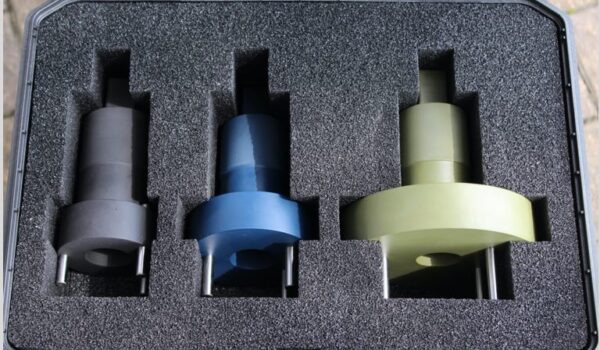

Closed Impeller System Product Numbers (PN’S): DUR31013CLI, DUR41013CLI, DUR6413CLI, AND DE3PSS

$3,623.40

Contact Us about this product

Closed Impeller System Overview

Closed Impeller System US Patent: #D841420 S

Drive End Socket Set US Patent: #D823658 S

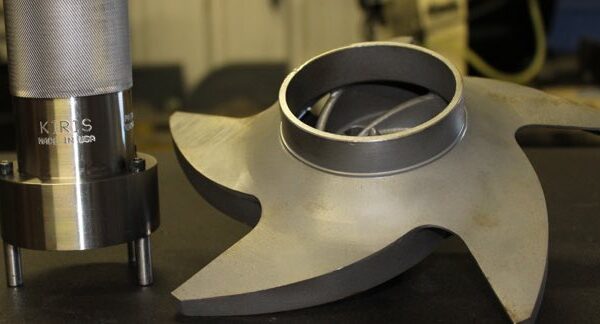

The closed impeller wrench enables you to safely remove damaged or sharp-edged impellers. In addition, it protects users from injury and prevents further damage to the equipment. Furthermore, the system frees both hands for safe torque application. Unlike traditional removal methods, the wrenches fit closed impellers and distribute pressure evenly around the eye. As a result, this even force makes it easier and safer to loosen stuck impellers.

Safer and Smarter Maintenance

In today’s industrial environment, having the right tools helps ensure safety and efficiency. Whether you’re buying for yourself or your team, modern technology plays a key role in protecting workers on the job.

This is especially true when working with heavy equipment in high-risk settings.

The KIRIS system works specifically with closed centrifugal pumps. It allows professionals to keep both hands free while applying torque.

As a result, the system reduces on-the-job injuries and protects critical internal components during impeller removal.

Why Closed Impeller Systems Require Special Attention

Closed impeller pumps are among the most commonly used in industrial applications—particularly in systems that handle volatile fluids. Because of their design, their internal components are protected by two metal plates, which makes them less visible and more difficult to inspect.

Despite their durability, these pumps tend to lose efficiency over time due to internal wear. To maintain performance, technicians must regularly check the system’s wear rings—a task that, in many cases, requires full disassembly

The Right Tool for the Job

Assembling and disassembling industrial process pumps can be both time-consuming and hazardous—especially without the right tools. In particular, using inferior equipment increases the risk of technician injury and can cause significant damage to pump components.

That’s where the closed impeller wrench system stands out. Its design distributes pressure evenly around the eye of the impeller. As a result, it helps remove broken or stuck components safely and efficiently. In doing so, it saves time, prevents equipment damage, and keeps your jobsite safer.

Additionally, the system is backed by a U.S. patent, giving you the assurance that it’s built to perform. With this tool in hand, you can complete complex jobs faster and with greater confidence.

Engineered for Industrial Demands

In any industrial environment, having tools you can trust isn’t optional—it’s essential. Your work quality and your team’s safety both rely on using the right equipment, day in and day out.

That’s why the KIRIS Closed Impeller System delivers unmatched durability, precision, and dependability—exactly what you need to tackle tough repairs with confidence. In addition, every set includes a limited lifetime warranty, giving you long-term peace of mind with every purchase.

Not sure which tool fits your application? Our team is here to help. Contact us today, and we’ll guide you to the system that best fits your equipment and environment.

How to Use the KIRIS Closed Impeller System

- Remove the coupling hub and any hardware from the shaft to expose the square end.

- Choose the correct drive end socket from your KIRIS kit, based on the shaft size.

- Secure the drive end socket onto the shaft, ensuring a snug, stable fit.

- Position the KIRIS impeller cap over the closed impeller, aligning the pin slots with the vane spacing.

- Slide the cap fully onto the impeller eye. Make sure it’s seated evenly and centered.

- Use a wrench on the drive end socket to hold or turn the shaft.

- Place a second wrench on the impeller cap and rotate it in the required direction to loosen the impeller.

- Apply steady, even torque until the impeller breaks loose and slides off the shaft.

- Reinstall the impeller by reversing the process after cleaning or maintenance.

Closed Impeller System Demo & Instructions

DIMENSIONS: 21.00 X 21.00 X 19.00

Featured On & Trusted By

Our tools have been highlighted across the pump industry on these respected platforms:

- Specialty Maintenance Products (SMP)

- Empowering Pumps & Equipment

- PumpWorks

- BIC Magazine

- Empowering Pumps & Industry Conference (EPIC)

- Iowa Pump Works

- Indiana Pump Works

- Wisconsin Pump Works

- Service Pump & Supply

- Gorman‑Rupp Company

- Mosher Pumps

- Grundfos Pumps

- Progressive Pumps

- Engineered Sealing Solutions

- Fybroc Pumps Inc.